SOLUTION FOR SHIELD TUNNELING/PILE DRIVING MUD TREATMENT

With the development of the economy, environmental polution is increasing day by day, and protecting the environment has become an unshirkable responsibiltly and obligalion for everyone. Mud separation equipment can effectivelyseparate sol and debris, facitate mud water separation, resource reuse, improve engineering quality, and effectivelyreduce environmental pollution.

1. Sewage sludge

2. Mud enters the machine

3. Filter out clean water

4. Compact the mud cake

China Railway Fourth Bureau Shenzhen Shield Tunnel Slag Environmental Protection Treatment Project

Project Overview: This project is the third work area project of the first and second sections of the Shenzhen Metro Line 14 co built pipe gallery project of China Railway 4th Bureau Group Co., Ltd.

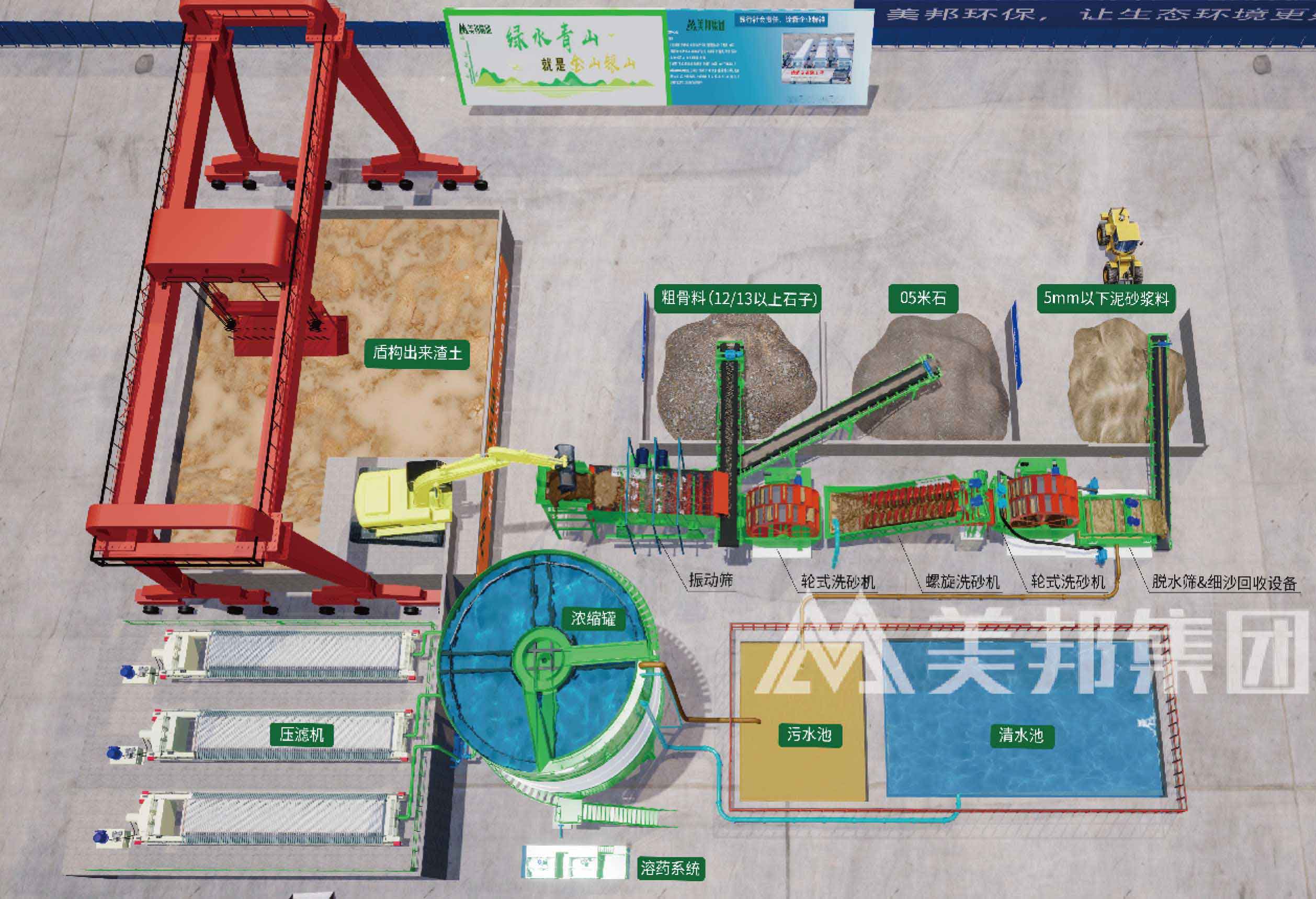

Project result: The design of the shield tunneling slag treatment project includes two parts: screening aggregates and sewage treatment system, ultimately obtaining four high standard sand and gravel aggregates, 12 stones, 10 stones, 05, and finished sand. After washing with water, the sludge is separated into mud and water by an environmentally friendly filter press. The dry sludge can be directly transported for backfilling, and the clean water can be recycled for use on the site.

China Railway 11th Bureau Shenzhen Shield Tunnel Slag Environmental Protection Treatment Project

Project Overview: This project is the shield tunneling slag treatment project of the second branch of the fifth work area of the Qianhuang section of the Shenzhen Suiguan Shenzhen intercity railway, operated by China Railway 11th Bureau Group Co., Ltd.

Project result: The design of the shield tunneling slag treatment project includes two parts: screening aggregates and sewage treatment system, ultimately obtaining four high standard sand and gravel aggregates, 12 stones, 10 stones, 05, and finished sand. After washing with water, the sludge is separated into mud and water by an environmentally friendly filter press. The dry sludge can be directly transported for backfilling, and the clean water can be recycled for use on the site.