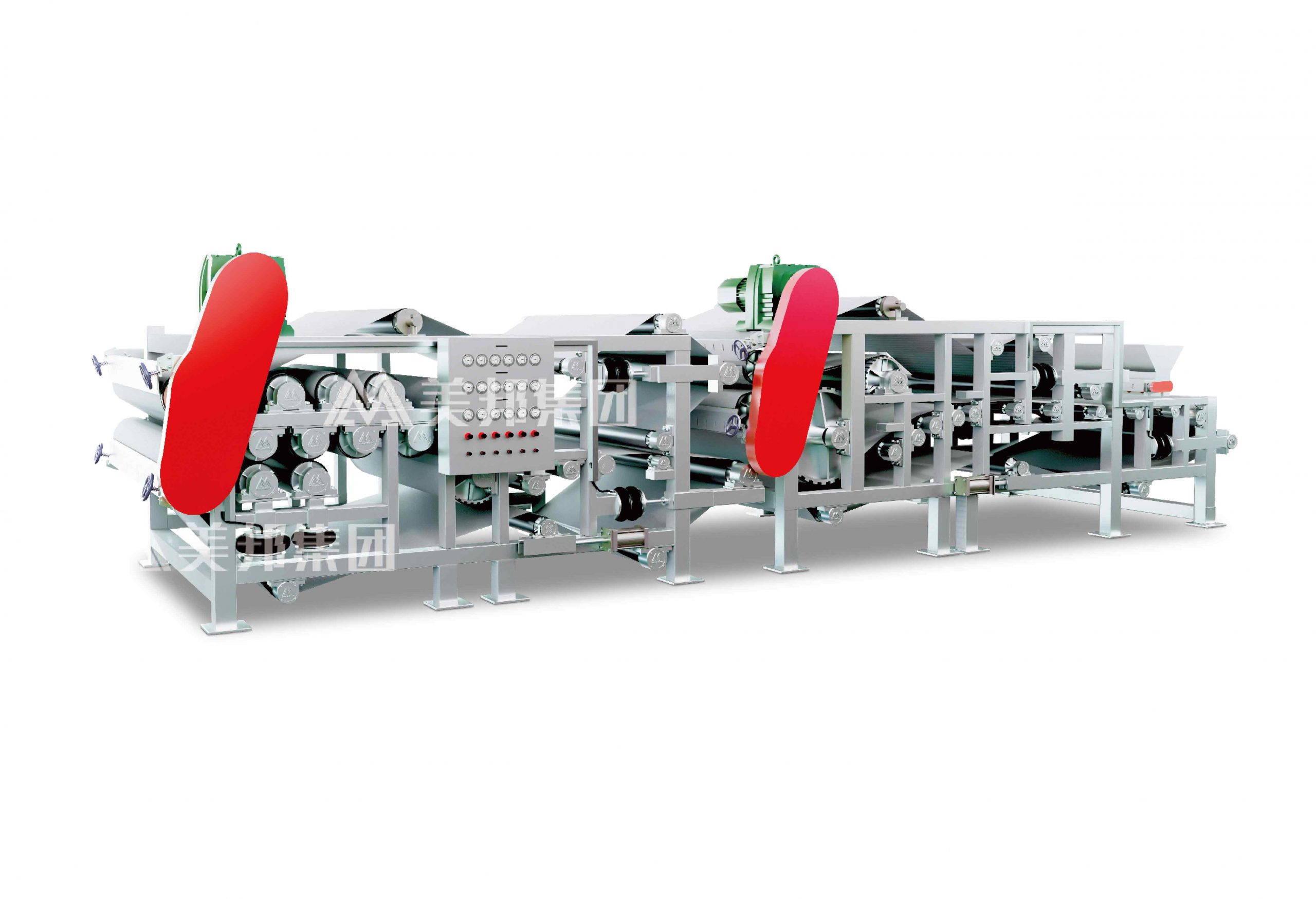

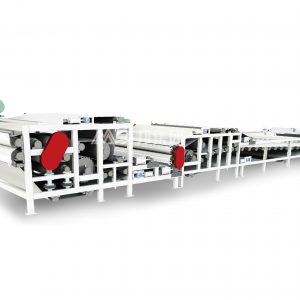

Dehydration treatment of cassava residue, potato residue, traditional Chinese medicine residue, tea residue, corn residue, rough beer residue, wood pulp fiber, sugarcane bagasse, coconut coir, wood pulp residue, sweet potato residue, sweet chrysanthemum residue, and animal manure residue such as cow manure

Product advantages

24-hour automatic continuoushoperation

Large processing capactyand less power consumption

Two independent pressing anddehydration zones

Slag that is particulary proneto material leakage

ligh and low dual headcombination design structure

Effectively reduce the moisturecontent of materials

Slag that is particulary proneto material leakage

ligh and low dual headcombination design structure

Effectively reduce the moisturecontent of materials

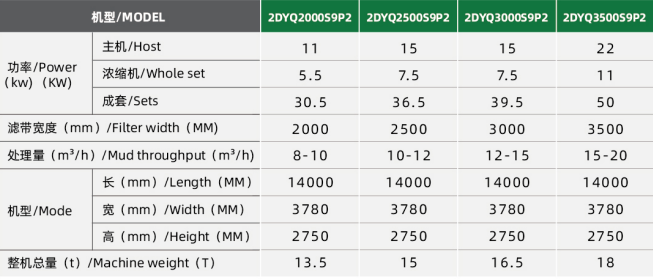

Technical parameter

Vietnamese cassava residue pressing and dehydration project

Project Overview: At the cassava residue pressing site in Vietnam, more than 400 tons of cassava residue are processed daily. The crushed wood residue is fed into the Meibang press machine for deep dehydration through belt feeding, and the resulting cassava residue can be directly stacked and packaged.

Project Overview: At the cassava residue pressing site in Vietnam, more than 400 tons of cassava residue are processed daily. The crushed wood residue is fed into the Meibang press machine for deep dehydration through belt feeding, and the resulting cassava residue can be directly stacked and packaged.

Xinjiang Potato Starch Residue Squeezing and Dehydration Project

Project Overview: At the cassava pomace pressing site in Xinjiang, over 100 tons of potato pomace are processed daily. After washing and crushing the potato starch, the crushed potato pomace is fed onto a conveyor belt for deep dehydration in a Meibang press machine. The resulting potato pomace can be directly stacked and packaged.

WHAT’S YOUR SEPARATION CHALLENGE?

MEIBANG Separation is the world’s leading separation specialist with

the broadest technology portfolio and more than 50 specialists in the factory. For more than 20 years, we have been a driving force in the

evolution of separation solutions and services for industries ranging from environment to food, chemicals, and mining & minerals.In industry, any sludge or slurry is sourced from food processing wastes, pulp and paper wastes, chemical sludges, pharmaceutical wastes, industrial waste processing sludges, and petrochemical wastes. In China, we have a well-established supply chain system that allows us to tailor dehydration solutions to meet specific customer needs.we have the solutions and services to transform your business to meet tomorrow’s changing demands – wherever you are and whatever your separation challenge. Ask your separation specialist.

MEIBANG Separation is the world’s leading separation specialist with

the broadest technology portfolio and more than 50 specialists in the factory. For more than 20 years, we have been a driving force in the

evolution of separation solutions and services for industries ranging from environment to food, chemicals, and mining & minerals.In industry, any sludge or slurry is sourced from food processing wastes, pulp and paper wastes, chemical sludges, pharmaceutical wastes, industrial waste processing sludges, and petrochemical wastes. In China, we have a well-established supply chain system that allows us to tailor dehydration solutions to meet specific customer needs.we have the solutions and services to transform your business to meet tomorrow’s changing demands – wherever you are and whatever your separation challenge. Ask your separation specialist.

Reviews

There are no reviews yet.