application scenarios: Desalination and dehydration of cocopeat,cocohusk blocks, cocohusk shreds, etc.

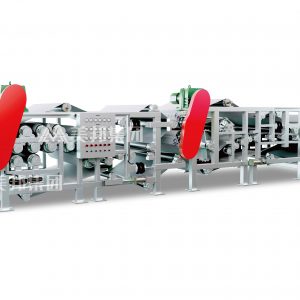

The structural design of six sets of roller desalination and dehydrationhas a leading international level of technology, effectively solving theproblem of high salinity in coconut coir fiber and minimizing the salinityand moisture content of the material to the greatest extent possible.

Product advantages

24-hour automatic continuoushoperation

Lange processing capacityand less power consumption

Easy to operate, easy tomaintain.

Especialhy suitable for slagwith long filber

6 sets of roller desainationand dehydration

Effectivety reduce the moisturecontent of matenals

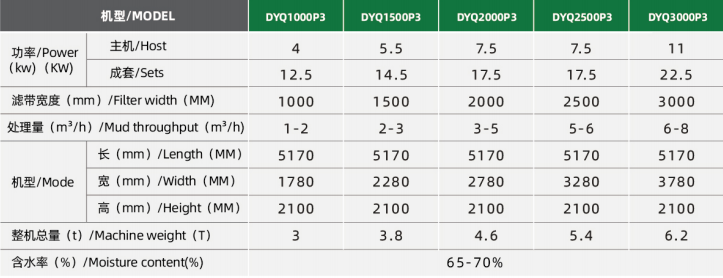

Technical parameter

PROCESS FLOWCHART OF INTELLIGENT COCONUT COIRPRODUCTION LINE SYSTEM SOLUTION

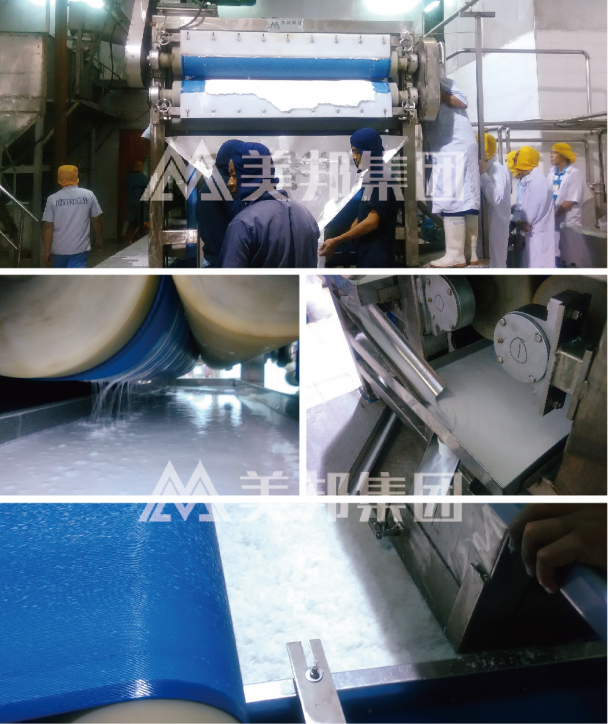

Coconut coir pressing and dehydration projects both domestically and internationally

Project Overview: It is necessary to desalinate the local coconut coir and then dehydrate it. We recommend suitable roller pressing equipment according to the situation of different customers. The main venues for use are Malaysia, Thailand, Vietnam, India, the Philippines, Sri Lanka, Hainan, Brazil, and other places.

Malaysia Food Grade Coconut Crushing and Dehydration Project

Project Overview: About 3 tons of coconut milk per hour needs to be dehydrated, and the resulting slurry enters a bucket for collecting coconut milk. The pressed coconut milk is then packaged into edible grade coconut milk.

Chinese medicine residue and pulp residue pressing and dewatering project

Project Overview: About 2-6 tons of traditional Chinese medicine residue and pulp residue are subjected to deep pressing and dehydration treatment per hour, and are then processed through three sets of roller presses to obtain the final product

The material has a low moisture content and can be directly packaged and shipped out.

WHAT’S YOUR SEPARATION CHALLENGE?

MEIBANG Separation is the world’s leading separation specialist with

the broadest technology portfolio and more than 50 specialists in the factory. For more than 20 years, we have been a driving force in the

evolution of separation solutions and services for industries ranging from environment to food, chemicals, and mining & minerals.In industry, any sludge or slurry is sourced from food processing wastes, pulp and paper wastes, chemical sludges, pharmaceutical wastes, industrial waste processing sludges, and petrochemical wastes. In China, we have a well-established supply chain system that allows us to tailor dehydration solutions to meet specific customer needs.we have the solutions and services to transform your business to meet tomorrow’s changing demands – wherever you are and whatever your separation challenge. Ask your separation specialist.

Reviews

There are no reviews yet.